5 Reasons to Upgrade to an LED Exposure Unit

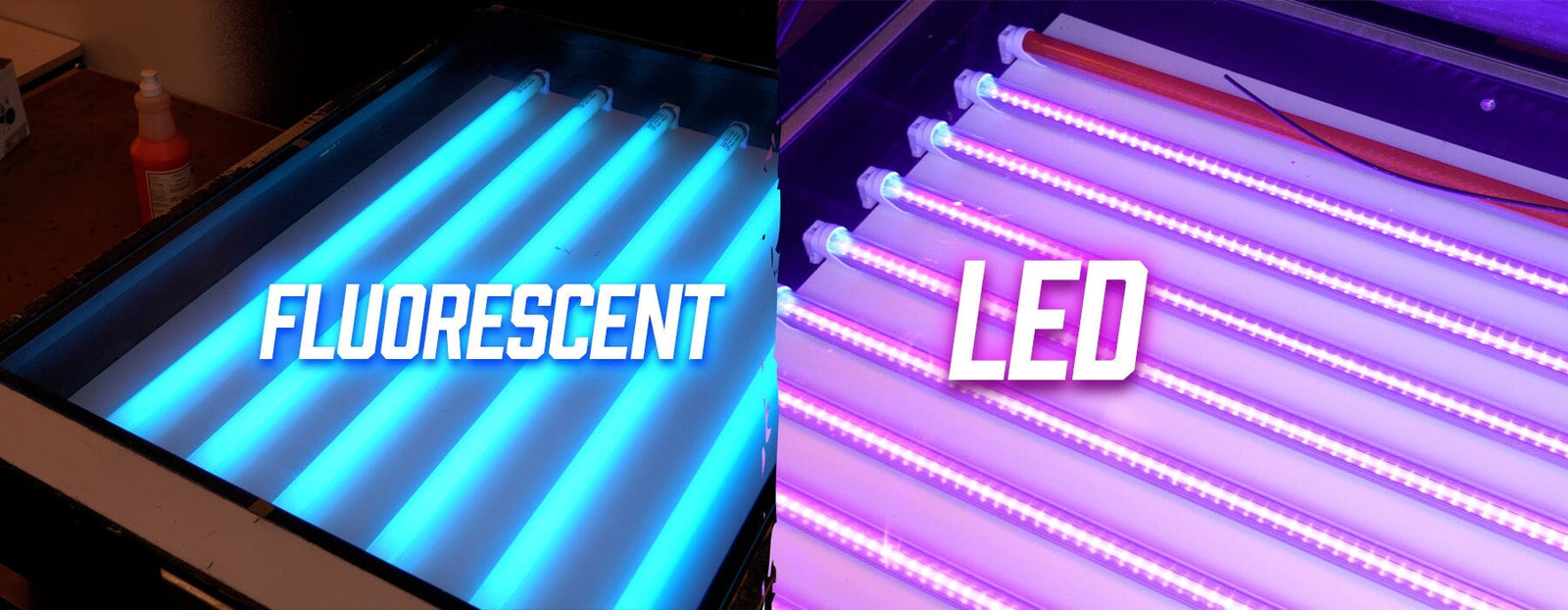

If your screen printing shop is still using an old fluorescent tube exposure unit, it might be time to level up your darkroom. In this post, we’re breaking down why LED exposure units aren’t just a luxury—they’re a smart investment that saves money, boosts efficiency, and improves print quality across the board.

Whether you're running a small shop out of your garage or managing a mid-size production space, this upgrade can completely change your workflow. Let’s dive in.

1. Save Money on Replacement Bulbs

Fluorescent tubes don’t last forever. They dim over time and need frequent replacement—and with U.S. regulations phasing out certain types due to mercury content, they’re getting harder to find and more expensive.

LED bulbs? They last up to 50,000 hours and don’t degrade in intensity. That’s years of reliable exposure without the hassle of shopping for outdated tubes.

2. Better Screen Quality with Sharper Exposures

Fluorescent bulbs emit light in all directions, which causes scattered exposure and cross-edging on your screens. That lack of precision can soften your artwork edges.

LEDs, on the other hand, provide a direct, focused light source—especially when using 405nm UV LEDs optimized for today’s emulsions like Chromaline ChromaLime and Baselayr Complete. The result? Sharper detail and more consistent stencils.

3. Cut Exposure Times in Half (or More)

Time is money in the print shop. A screen that used to take 90 seconds to expose with tubes can now be exposed in as little as 28 seconds with a 405nm LED unit.

That means you can prep more screens in less time, speeding up your production schedule without sacrificing quality.

4. Consistent, Reliable Exposures

One of the biggest frustrations with fluorescent exposure units is inconsistency. As tubes wear down, exposure times become a guessing game. You end up overexposing or underexposing screens without realizing it—until the washout fails.

With LEDs, what you set on day one is what you’ll get five years from now. It’s plug-and-play reliability, which removes the guesswork from your workflow.

5. Energy-Efficient and Eco-Friendly

LEDs convert 95% of their electricity into usable light, while fluorescent tubes waste energy—especially at connection points. Plus, fewer replacements mean less waste, less glass, and less mercury in landfills.

Your bottom line and the environment both win.

Ready to Upgrade?

Making the move to LED isn’t just about newer tech—it’s about smarter business. Lower costs, better screens, faster production, and a cleaner workspace.

Explore our full line of LED Exposure Units

Pair with Quality Film, Chromaline ChromaLime Emulsion and Baselayr Complete Emulsion optimized for 405nm UV light

Got questions? Drop a comment on the video or reach out to our team—we’re here to help you light up your darkroom the smart way.