A Guide to Creating an Underbase in Adobe Illustrator

Creating an underbase for your art is important to make sure your design comes out as clean and vibrant as you imagined it. Want to know how to do it?...

Free Shipping in the Con. US Learn More

Creating an underbase for your art is important to make sure your design comes out as clean and vibrant as you imagined it. Want to know how to do it?...

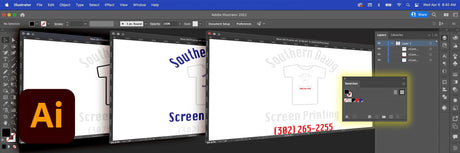

For some screen printers, using Illustrator to separate colors can be overwhelming at times. Luckily, the main roadblock people run into is over-thinking the process. In this video, Luke Ryerkerk...

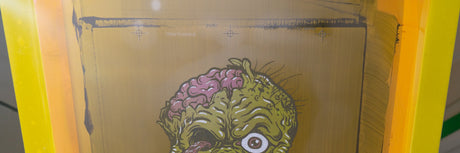

Screen printing doesn’t have to just be about printing t-shirts. You can print on just about anything with the right tools and process. One unique material to print on is...

Have you already done three standard head cleanings, and your print heads are still clogged? Don’t worry, all is not lost! Kevin Carle explains how you can do a manual...

Screen printing isn’t just about printing T-shirts. You can print so many different things: tote bags, posters, heat transfers, boxes, and more. One creative way to showcase your screen printing skills and add a...

When you look at all the different mesh counts of screens, do you feel overwhelmed? How do you know which mesh count to choose? They range as low as 38 to...

Single-use plastic is wasteful. Every year, more and more plastic ends up in landfills, waterways, oceans, and even our bodies. It’s almost impossible to get away from single-use plastic in...

Wet-on-wet printing can save printers a ton of time since they do not have to wait on the flash. However, wet-on-wet printing is a technique that isn’t mastered overnight. You...

Neck labels are a great way to show off a brand. Since it’s inside the shirt, it’s a popular and subtle way to give customers a branded experience without being...

Plastisol ink is a popular ink choice. From beginner to auto shops, plastisol ink is a game changer. But do you know when it’s really ready to use? Do you...

Mixing ink is an art form. Sometimes you’ll mix your Pantone ink just right, following the formula, but when you go to print, the Pantone color looks totally wrong. No...

No matter what size your screen printing operation is or what market it caters to, the goal is to get jobs through the shop and out the door on time...

Creating a dark film positive is essential to getting a good screen and a good print. If your film is too light, it won’t expose correctly and you’ll lose valuable...