A Guide to Printing on Youth Apparel

Printing on youth apparel seems simple, right? Everything is smaller, but as long as you size everything to fit, it shouldn’t be a problem. Turns out, it’s a little more...

Free Shipping in the Con. US Learn More

Printing on youth apparel seems simple, right? Everything is smaller, but as long as you size everything to fit, it shouldn’t be a problem. Turns out, it’s a little more...

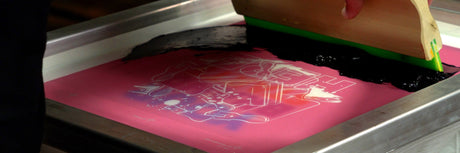

Starting in screen printing is exciting—but it’s easy to hit some bumps early on. Whether you’re printing out of a garage or setting up a side hustle, there are a...

Screen printing heat transfers can seem daunting but in reality, it’s fairly simple. If made properly, plastisol heat transfers can last almost as long as a screen prints and can be...

Printing with discharge ink is a fantastic way to create a vibrant print that's unbelievably soft. Discharge printing isn't for everyone though. Let's discover what is discharge, how it works,...

Why bother customizing the boxes you ship garments in? It's actually a small, but significant way to stand out from the crowd and look incredibly professional. That package is the...

Whether you're wanting a distressed style print for fun or professionally, Colin takes us through what you need to know! In this video you'll find great tips on distressed printing...

Ready to start screen printing? It's a big jump, but it's so worth it. To build your shop, you will need to obtain some equipment and supplies. Our Sales and...

Printing on nylon is a struggle. Many variables and differences in the material can make print jobs difficult. Once you get the process right, it’s a cinch. Jonathan Overmeyer at...

Every printer wants to save time and cash, right? Most screen printers know the most common time-saving hacks: optimizing print setup, keeping a stock of burned screens handy, and getting...

Emulsion remover removes emulsion. Seems simple, right? This chemical reclaims stencils faster with a concentrated emulsion remover solution. The chemistry breaks down emulsion when applied to a screen, and can be used in...

Quick Response codes, or QR codes, are everywhere. You sit down at a restaurant and to read the menu, you have to scan a QR code. You walk through a...

Each printer has their own unique story of why they got into screen printing. Some wanted to start their own clothing line. Others found it as a way to make...

Every printer wants to make money. You don’t want to lose profit on a job, but don’t want to turn potential customers away. So what do you do? Set a...