Which Screen Printing Kit is Right for Your Shop?

So you’re looking to start up a shop, but don’t know where to start. Maybe you want to upgrade your equipment, but hate comparison shopping. Well, there’s a solution. Buying...

Free Shipping in the Con. US Learn More

So you’re looking to start up a shop, but don’t know where to start. Maybe you want to upgrade your equipment, but hate comparison shopping. Well, there’s a solution. Buying...

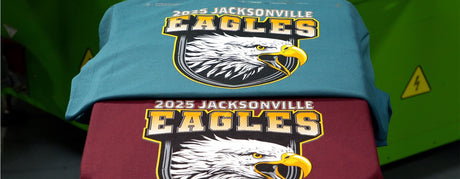

Screen printing heat transfers can seem daunting but in reality, it’s fairly simple. If made properly, plastisol heat transfers can last almost as long as a screen prints and can be...

Switching from a manual press to an automatic one is an exciting step for any screen printer looking to scale up their operations. While an auto press can speed up...

As much as a new business owner may wish and strive for it, not all have a budget to cover all their startup expenses. So, decisions have to be made...

There’s a lot to consider when talking about print placement on a garment. How tall should it be? Where should it be placed? Don’t worry about having all the answers....

Ever dreamt of whipping up your own custom tees, totes, and more from the comfort of your space? Meet the Screen Printer Starter Press—your new go-to in the DIY screen...

Imagine buying screen printing supplies and not having to pay taxes. What a dream, right? If your screen printing business is a registered LLC, that dream can be a reality....

Providing the best customer service means staying stocked up on inventory and ready to print at all times. It only takes losing a good customer due to supply issues one time,...

When you buy a bucket of plastisol ink, it might have been sitting on a shelf for a bit before it got to your shop. You might notice that your ink...

Imagine this: you walk into a conference center in Portland, Oregon, finding yourself surrounded by creative entrepreneurs just like you. On your left, a stunning print on a t-shirt catches...

You know the struggle: your conveyor dryer breaks down, and without it, you can’t run at the volume you need in order to meet deadlines. You need a new conveyor dryer, but...

Printing multi-color designs is a skill all printers need. White single-color prints are a screen printer’s bread and butter. A multi-color design takes skill, tight registration, and a bit of...

Have you seen the all-new Riley Hopkins 250: Lee Stuart Screen Edition Printing Combo? It features equipment — Riley Hopkins 250 6x4 Press and Multi-Station Press Cart — you’ve come to know and love with...