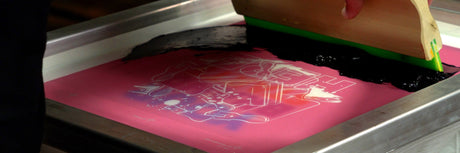

Best Practices when Printing Multi-Color Posters with Green Galaxy Water-Based Ink

Ever looked around at your walls and thought “This could use some pizzazz?” Screen printing professional Jamie is with you. The walls of her print studio were bland and boring....