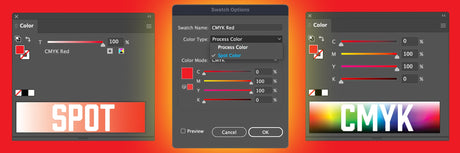

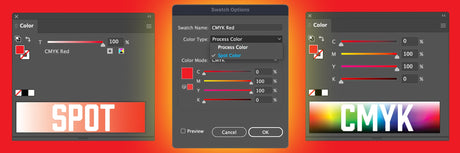

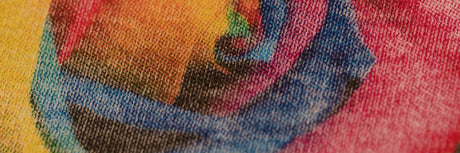

CMYK vs. Spot Color vs. Simulated Process Printing

Okay, so you’ve heard their names, CMYK Process, Spot Color, and Simulated Process, but what are they? What sets them apart from one another and what is the best use...

Free Shipping in the Con. US Learn More

Okay, so you’ve heard their names, CMYK Process, Spot Color, and Simulated Process, but what are they? What sets them apart from one another and what is the best use...

Have you ever wanted to screen print CMYK, but didn't know where to start? Here's a crash course. In the video, print expert Colin Huggins shows you how to do...

Printing posters are a great way to test out prints and get your work past the t-shirt industry. With the proper technique and a little bit of patience, you can...

Prepping a screen for water-based inks can be a little more tricky than plastisol. The print deposit is thinner, the ink dries on the screen over time, and the ink...

Water-based ink is becoming more and more popular. With more shops turning to greener methods, printing with water-based ink can be nicer on the environment and your health. Many printers...

Ever had a stencil break down during production? It sucks. Unless you have backup screens ready, production will come to a halt. Your time is valuable. For jobs that need...

Screen printers debate which is better: plastisol or water-based ink. Some printers start out with plastisol ink, while others opt to jump right into water-based printing. But how are they...

Every screen printer should have a heat press and teflon sheets. Not only will you be able to offer vinyl and foil as a service, you’ll be able to use the heat press...

Intrigued by water-based inks? Water-based inks are great because they feel so soft on the garment and simple to print basic jobs, but it becomes challenging when printing complex art...

Let’s face it. Screen printing is dirty, messy, and toxic at times. From the chemicals, garment manufacturers, chemical waste, to water pollution, screen printing has a long road ahead to becoming...

Different mesh counts are used for different applications in the screen printing process. What is mesh count? Well, mesh count is a measure of how many threads of polyester (used to be silk, centuries ago, hence...

Face masks aren't going away. Businesses are buying them for their employees. Citizens are wearing them when they run errands. Face masks are a way people can contribute to protecting...

Face masks are booming right now. To cater to the current market, printers are offering face masks, giving the option to personalize them. While fulfilling face mask orders does help...