It’s no secret that lasers are cool. They’re not just for laser tag or entertaining cats. Screen printers can take advantage of laser precision using a laser guiding system to line up prints on press. Why is this system a game-changer for printers? Let’s find out.

WHAT IS THE LASER GUIDING SYSTEM?

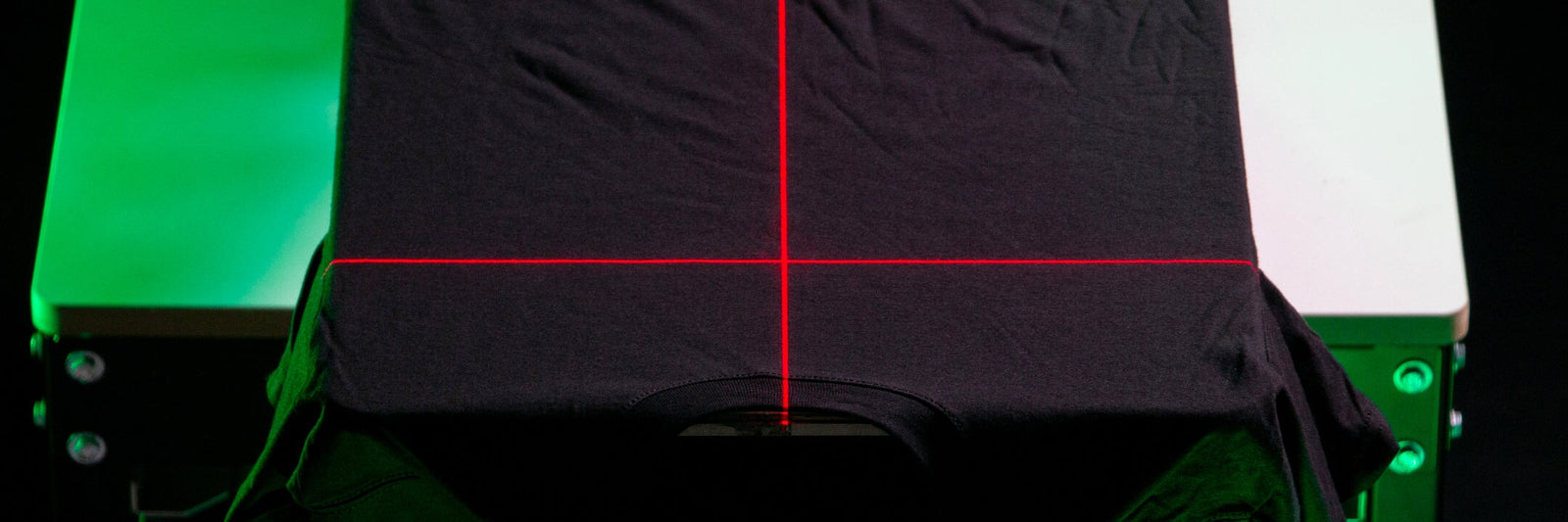

Used just like a T-square and sharpie, the laser system creates a bright crosshair for registration lines on the platen that can be seen on the platen and on top of the garment. The laser produces two, illuminated crosshairs that are visible on platens, garments, and screens.

The laser system is super easy to install. You can spin the system 360 degrees, move it up and down, and move the laser 360 degrees. The Riley Laser Guiding System works for the Riley Hopkins AERO, WIN, Juniors, 250, 300, and 350 presses.

RELATED: SUPPLY AND EQUIPMENT UPGRADES THAT IMPROVE PRODUCTION AND QUALITY OF PRODUCT

WHY SHOULD I USE LASERS?

The better question is why not? The old-school way to align prints is to grab a t-square and sharpie and draw the lines yourself on each pallet. That process works, but it's definitely time-consuming. Your time is money. If there's a way for you to streamline a process, why not take advantage of it?

Load and align left chest designs, pocket prints, neck tags, and any other unique print placements with ease. No more guessing or re-marking lines on a pallet. With a laser, you can quickly line up designs, print, and move to the next shirt with more precision. It simplifies setups, reduces the number of misprints, quickens prep time, and improves registration.

RELATED: A GUIDE TO INDUSTRY STANDARDS FOR SCREEN PRINT PLACEMENTS AND DIMENSIONS

HOW TO USE THE LASER GUIDING SYSTEM

To use the laser guiding system, simply turn it on and maneuver the laser to the proper position for the job you’re printing. When adjusting the laser system, make sure to move the entire system rather than the laser itself. For example, say you're going to be printing on the chest. If you tilt the laser to point at the chest, the lines will be crooked. Instead, move the entire system so the laser is above the chest rather than angled toward it.

RELATED: HOW TO GET THE PERFECT POCKET OR LEFT CHEST PLACEMENT ON ANY PRESS

Once you start using the laser guiding system, you’ll wonder what you ever did without it. Investing in an upgrade for your press is worth the money, and will save you tons of time in the future.